McLanahan offers a wide range of solutions that can assist producers with fines recovery by eliminating or reducing the need for settling/tailings ponds, freeing up valuable time and land resources. These fines recovery solutions can also help producers create an additional product with some market value, which can increase their profitability.

How Recovering Fines Can Reduce Settling Ponds

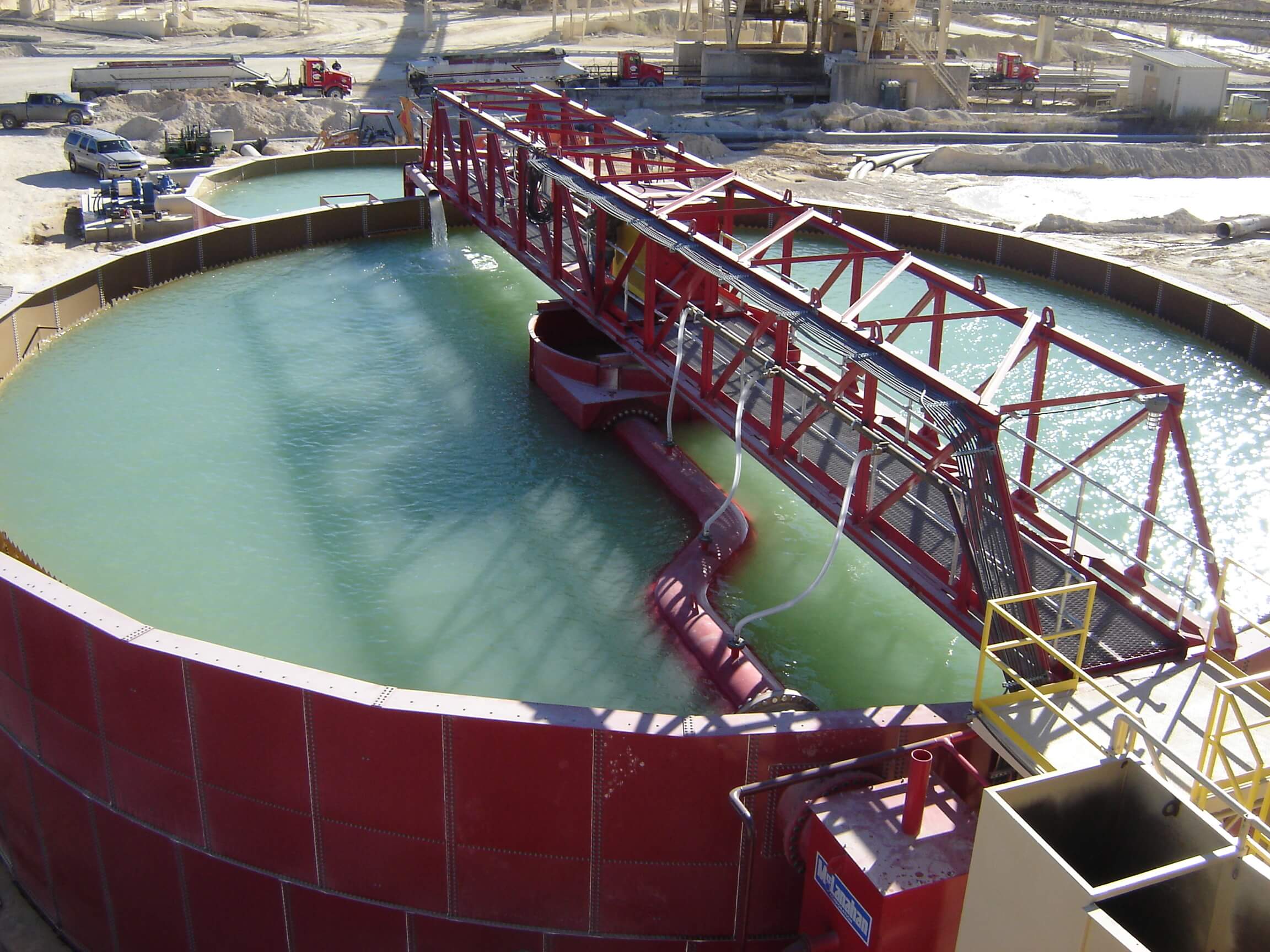

Settling ponds are commonly used to recover fines from the processing plant. Over time, gravity works to separate the fine material from the process water. After it settles to the bottom of the pond, the fine material must be pulled from the pond and stacked in stockpiles to dry. It’s a process that requires continuous management. Producers spend valuable time, energy, resources and capital cleaning out the settling ponds and stacking the fine material — all for a product that may or may not be usable in the end.

Treating wastewater in a settling pond is not the most sustainable method for dealing with fines. Though settling ponds are common, producers have other options when it comes to recovering fine material from their plant’s wastewater.

Capturing fines in an efficient way can save producers the time, energy and costs associated with handling the fine material. It can also reduce the frequency for which the settling ponds need dredged and decrease stockpile drying time.

Producers can capture fine material before it goes to a settling pond by using equipment that separates the fines from the process water and dewaters them to a dry, conveyable and stackable form. By utilizing fines recovery, producers can create an easy-to-manage, potentially saleable product from the fine material byproduct, as well as immediately reusable process water that can be recycled back to the beginning of the wash plant.

Recovering fines and recycling the process water can allow producers to reduce the size or extend the life of their settling ponds or, in some cases, eliminate their settling ponds altogether, creating a more sustainable site and leaving a smaller environmental footprint. It also saves producers from incurring the costs associated with cleaning their ponds and handling their material.