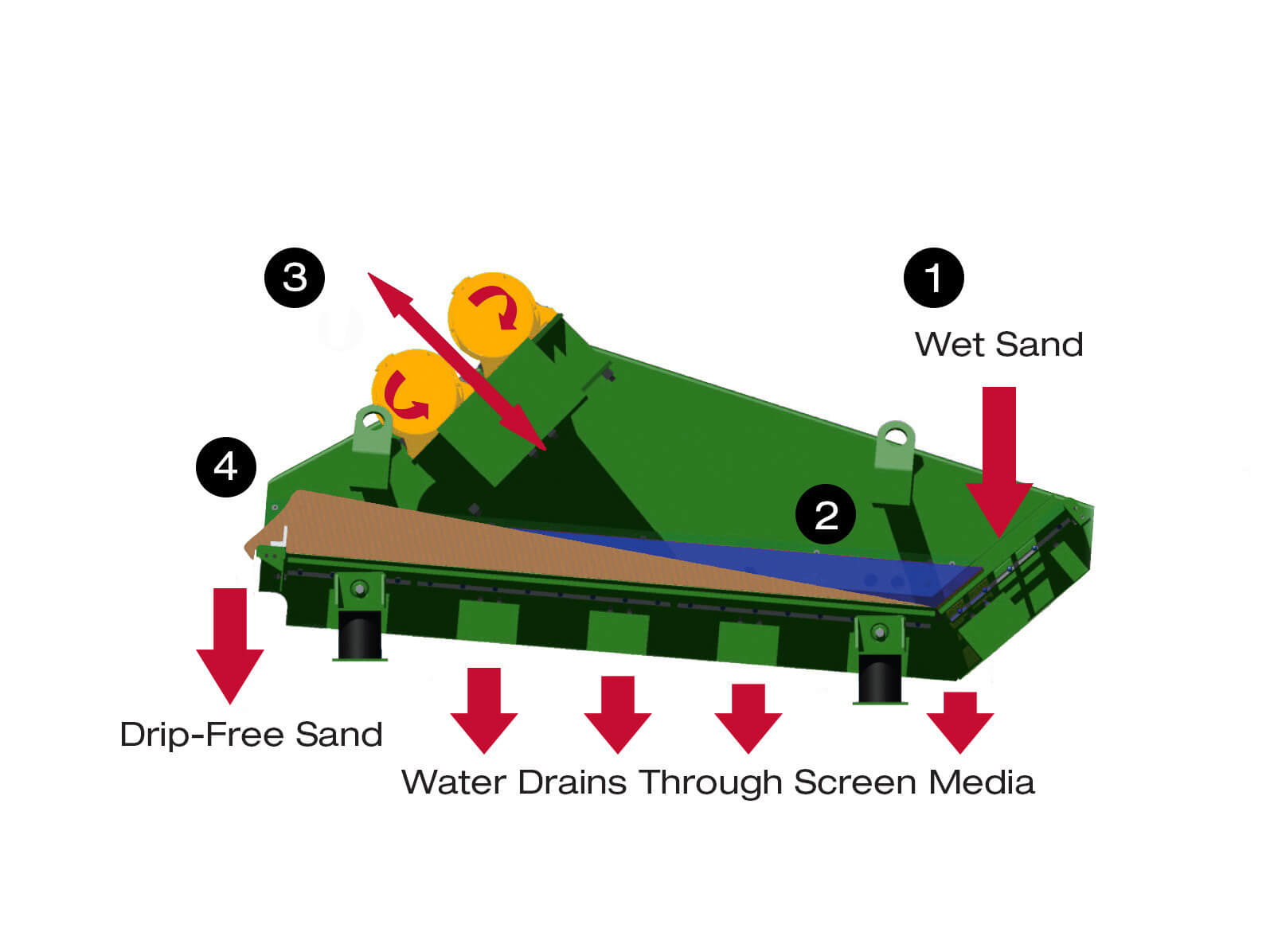

To dewater recycled sand effectively, the washed sand is fed onto the steep, downward inclined screen surface at the feed end of the Sand Dewatering Screen to achieve rapid drainage. A pool of water forms in the transition area as material builds up on the slightly upward inclined surface. Two counter-rotating vibratory motors create a linear motion at an angle to the screen surface. This rapid motion accelerates the solids upward and forward, forcing the liquid and small organic fibers to drain through the sand and through the screen surface. The sand is conveyed up the screen toward the discharge by this linear motion. The uphill slope of the screen, along with a discharge weir, creates a deep bed of sand that acts as a filter medium, allowing material much finer than the screen openings to be retained. Water and sand that pass through the screen’s surface are typically recycled back to the source or captured again in a Hydrocyclone system. This allows the process to attain recovery rates well over 90% while yielding a clean, dry sand product. In a sand separation system, the water held in the sand contains a small amount of organic material that acts as food for bacteria. As the water is pulled from the sand in a Dewatering Screen, it drags with it a portion of those small fibers, which exit with the water. This yields a cleaner sand without the use of additional fresh water. Screens can be fitted with a Derocker to remove oversize and tramp material from the bedding sand before it is dewatered. This Derocker removes large rocks, plastic, wood and other debris that can be problematic if it ends up in the sand bedding.