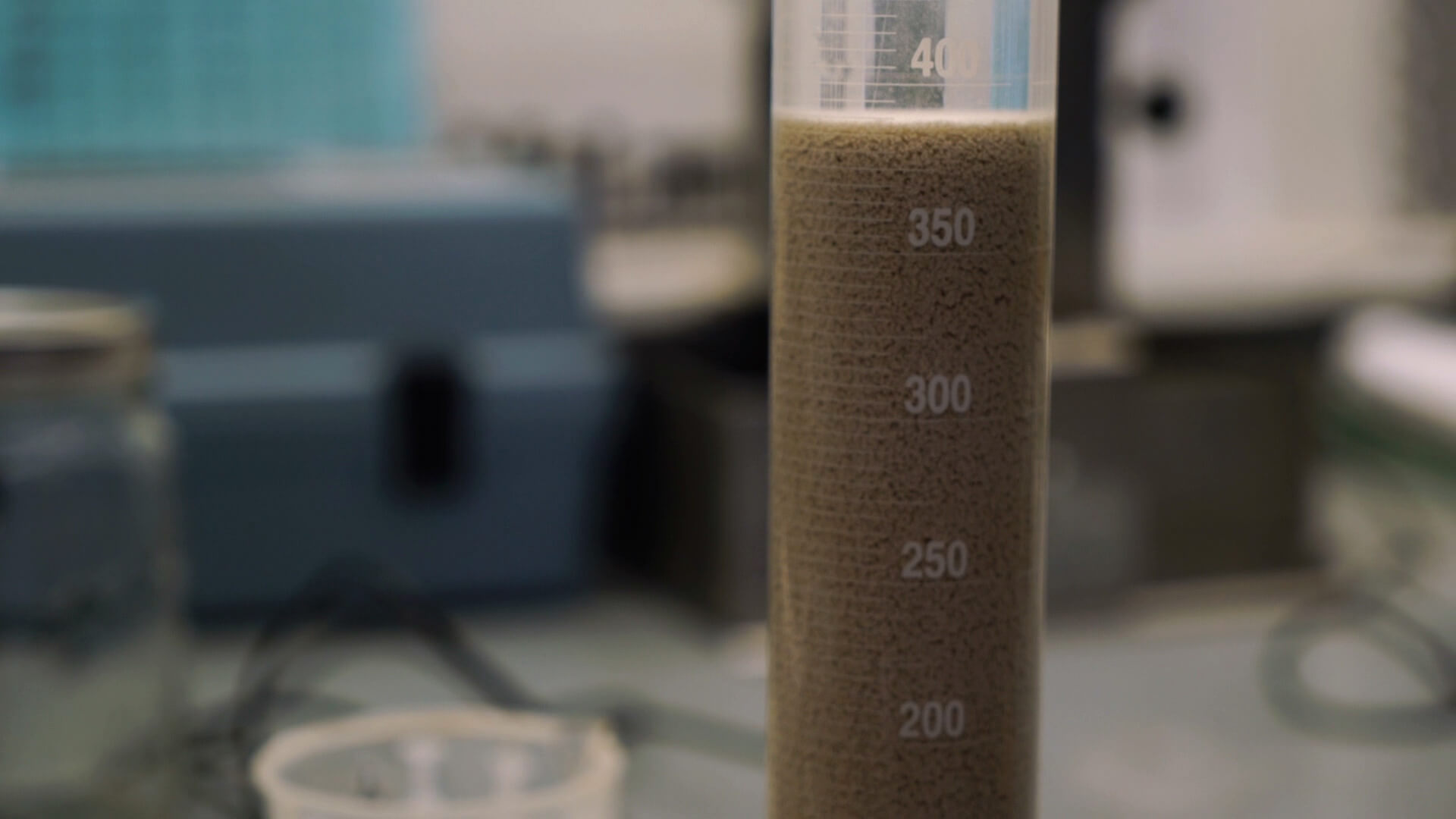

Lab Testing

McLanahan maintains and operates a minerals and aggregate laboratory staffed with full-time technicians and supported by trained mineral processing engineers to ensure the proper evaluation of your material.

McLanahan maintains and operates a minerals and aggregate laboratory staffed with full-time technicians and supported by trained mineral processing engineers to ensure the proper evaluation of your material.

Many of your inquiries will start off in our lab, where we characterize your material using a number of protocols, including both ASTM and in-house procedures we have developed for scale-up of our own unit operations.

Proper evaluation of your materials and interpretations of results ensures that the solutions we provide to you, whether greenfield or brownfield, simple or complex, are technically sound and cost-efficient for the life of the endeavor.

To speak to an expert or for more information regarding McLanahan’s ability to test your products, please contact sales@mclanahan.com.