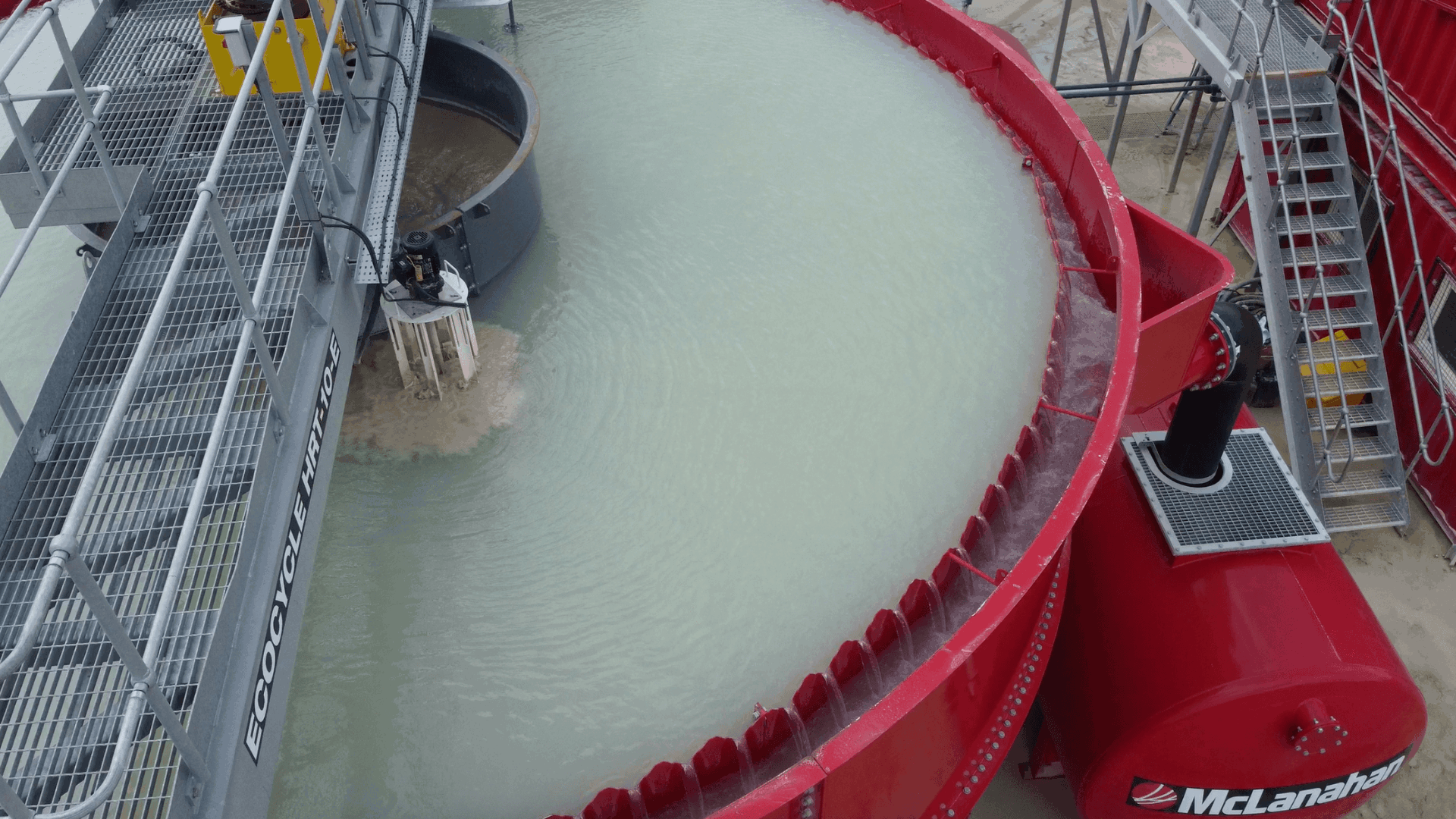

Tailings management is a broad term used to describe the separation of raw aggregates from the waste by-product that occurs when extracting aggregates from the ground. Optimized fines recovery and tailings management can provide numerous benefits to producers such as regulatory compliance, water conservation and improved plant operations.

Aggregates producers can optimize their operations by reclaiming fine particulates for further processing. Reusing process water will also allow producers to decrease costs and provide an environmentally sustainable alternative for water management.

Fines recovery is used to reclaim ultra fine particles as low as 75 µm (200 mesh), such as dust, dirt or fine silt, from the waste stream produced by the wet processing of aggregate. This is used to reduce the volume of material reporting to settling ponds, reducing pond maintenance and cleanout costs. In some cases, recovered solids can be sold and/or used as fill material. These fines can be processed using equipment such as Hydrocyclones and Separators™.

Solids and liquids are separated into two separate waste streams using equipment such as Filter Presses or Thickeners.